My big ZT thread > 15.4.08 25bhp/20lbft extra and track prep

It's amazing the number of people who'll jump on the bandwagon once all these replies and decisions have already been made!

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Jim i can complete understand your view point and it is one i admire,

the trouble is no matter what caused it Garrett/Honeywell would simply replace the arm/shaft and charge the earth for it, its a position they are in and will abuse, big companies are big companies because they are gready and cut throat. If they made indistructable turbos they would lose more money in lost sales for replacements/repairs than sales they gain from having the best indistructable product.

(dont forget to tell me i miss understood again and wrote all that for no reason)

the trouble is no matter what caused it Garrett/Honeywell would simply replace the arm/shaft and charge the earth for it, its a position they are in and will abuse, big companies are big companies because they are gready and cut throat. If they made indistructable turbos they would lose more money in lost sales for replacements/repairs than sales they gain from having the best indistructable product.

(dont forget to tell me i miss understood again and wrote all that for no reason)

- FezzR

- God Damn Lazy

- Posts: 11755

- Joined: Sun Apr 21, 2002 7:27 pm

- Location: Wanaka, NZ

I agree with the part saying that Honeywell/Garrett (or in this case Turbo Technics) would normally replace the wastegate assembly, as that would be far less time-consuming and more straight-forward than repairing the damaged part. I can't say I agree that they willingly design, and spend hours of testing on products that they hope will fail in their lifetime so they can charge high rates for when they repair them. I know lots of products lend themselves to that sort of marketing plan, but a 100,000rpm turbo isn't one such product in my eyes.

I spoke to them again today, and they've confirmed that the actuator pin is indeed welded in place. I've sent a fully-dimensioned model of the pin (they have over twenty of them listed) so once they've identified the one I need, it'll be sent to me at a total cost of around £15

I spoke to them again today, and they've confirmed that the actuator pin is indeed welded in place. I've sent a fully-dimensioned model of the pin (they have over twenty of them listed) so once they've identified the one I need, it'll be sent to me at a total cost of around £15

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

i didnt mean that they would design them to fail, meerly that they would not over engineer them.heeman10 :I agree with the part saying that Honeywell/Garrett (or in this case Turbo Technics) would normally replace the wastegate assembly, as that would be far less time-consuming and more straight-forward than repairing the damaged part. I can't say I agree that they willingly design, and spend hours of testing on products that they hope will fail in their lifetime so they can charge high rates for when they repair them. I know lots of products lend themselves to that sort of marketing plan, but a 100,000rpm turbo isn't one such product in my eyes.

It is obviously within thier interest to make them outlast a warrenty period. Also although we are talking about turbos in general and designing a 100,000rpm turbo to fail wouldnt be a good idea (hense you rarely see a turbine failure) things like the actuator, nuts, bolts, washers, seals and the like are a lot less critical (on the whole) and under less strain ans therefore less care taken.

bargin as long as it doesnt take much to fit? cant really tell from pics but you could end up having to strip bits off the turbo and obvious potential like snapping bolts etc then present themselfs, horrible when simple things mount up like thatheeman10 :I spoke to them again today, and they've confirmed that the actuator pin is indeed welded in place. I've sent a fully-dimensioned model of the pin (they have over twenty of them listed) so once they've identified the one I need, it'll be sent to me at a total cost of around £15

- FezzR

- God Damn Lazy

- Posts: 11755

- Joined: Sun Apr 21, 2002 7:27 pm

- Location: Wanaka, NZ

Update

I removed the external half of the exhaust housing as I was clearly going to get little done without doing so. I was hoping to keep it on just so I didn't have to damage/replace the insulation kit as it wasn't cheap, but with care I think it will go back without issue.

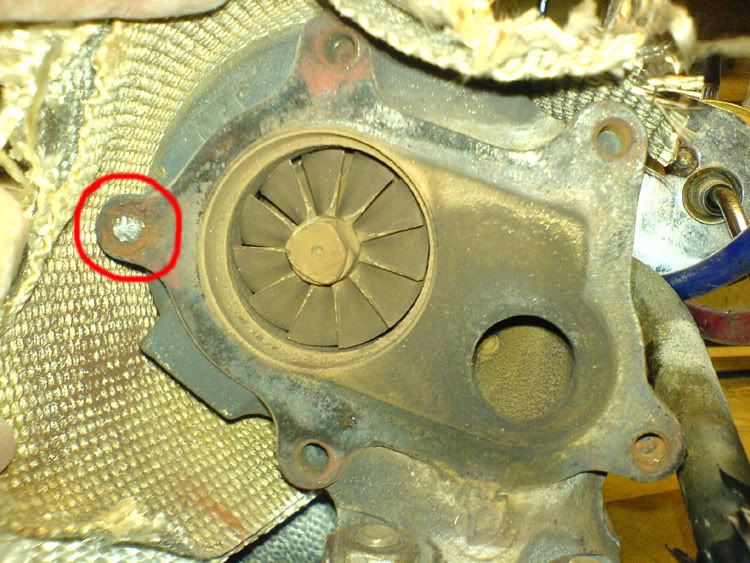

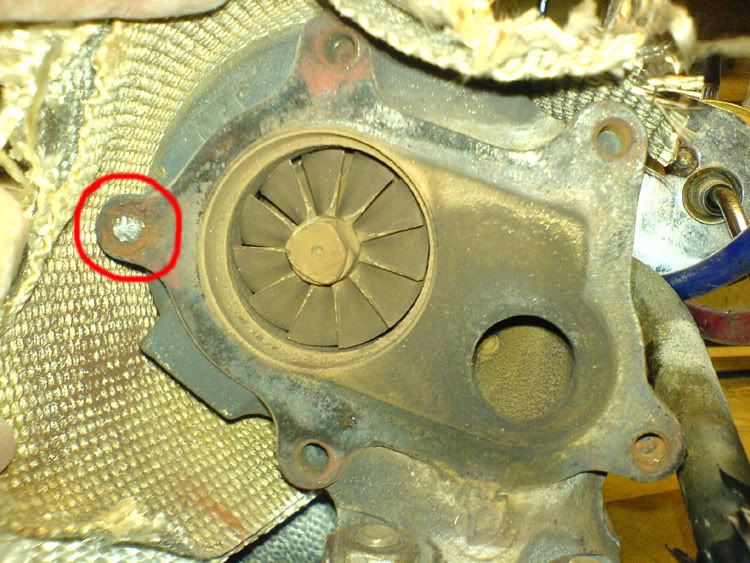

As expected, a bolt sheared off in the exhaust housing with very little torque applied at all, which is a real nuisance. All five bolts cracked loose with hardly effort and almost spun out, but this particular one gave up and sheared:

And here is the underside of the wastegate lever arm where the pin broke out:

Some random shots comparing my T3 to a FRST T2...

Exhaust housings (T3 on left):

Compressor housings and impellor faces (T3 on right):

Compressor housings with their respective exhaust housings:

I removed the external half of the exhaust housing as I was clearly going to get little done without doing so. I was hoping to keep it on just so I didn't have to damage/replace the insulation kit as it wasn't cheap, but with care I think it will go back without issue.

As expected, a bolt sheared off in the exhaust housing with very little torque applied at all, which is a real nuisance. All five bolts cracked loose with hardly effort and almost spun out, but this particular one gave up and sheared:

And here is the underside of the wastegate lever arm where the pin broke out:

Some random shots comparing my T3 to a FRST T2...

Exhaust housings (T3 on left):

Compressor housings and impellor faces (T3 on right):

Compressor housings with their respective exhaust housings:

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

somewhere like that i would put a bolt with a nut above the wastegate arm and then another pair of nuts after the actuator to form a very secure lock on the actuator.

if the pin is simply welded in place then a bolt is going to be more than up to the job.

i know it does seam a bit of a bodge way of doing it but the only reason that it isnt a bolt in the first place is for ease of fitting (reduce time by just clipping a bolt on) in the factory.

if the pin is simply welded in place then a bolt is going to be more than up to the job.

i know it does seam a bit of a bodge way of doing it but the only reason that it isnt a bolt in the first place is for ease of fitting (reduce time by just clipping a bolt on) in the factory.

- xrsi

- XR(ustyAtTheMo)SI

- Posts: 7351

- Joined: Thu Jan 01, 1970 1:00 am

- Location: shropshire

- Excursion

- Bulletin Board User

- Posts: 15265

- Joined: Thu Jan 01, 1970 1:00 am

- Location: Skynet

- Your car: Ford Fiesta

Car: 1990 Ford Fiesta XR2i

James - True, but it'd actually end up looking pretty darn messy. For simplicity's sake, I'd do that, but in terms of looks and serviceability, it's not a great idea, and I'd rather retain the circlip/spring clip method of retaining the actuator rod end

Mark - Yup, but it's a pretty turd wastegate arrangement in terms of flow, even in relation to the T2!! I want a compressor map for this turbo, but can't even find a .42 A/R T3 compressor map, let alone one for this particular impellor trim! It's running a touch rich now, so I'm thinking of taking it to MSD for a "setup", which is pretty damn in-depth, and I wouldn't mind nudging the boost up a bit if it would be worth it efficiency-wise.

Mark - Yup, but it's a pretty turd wastegate arrangement in terms of flow, even in relation to the T2!! I want a compressor map for this turbo, but can't even find a .42 A/R T3 compressor map, let alone one for this particular impellor trim! It's running a touch rich now, so I'm thinking of taking it to MSD for a "setup", which is pretty damn in-depth, and I wouldn't mind nudging the boost up a bit if it would be worth it efficiency-wise.

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

cant remember off handwithout looking at the whole setup on the car, but as for looks isnt the whole thing covered by the turbo anyways so that wouldnt be such a prob, but yes - serviceability could be a right pain in the arse..... i would have just done it that way and not cared bout the extra time needed if i had to take it off again  but saying that i dont intend to take it off regularly.

but saying that i dont intend to take it off regularly.

i think i found a compressor map for a .42 T3 when doing a uni assignment, will have a look!

EDIT - is this any good to you...

http://not2fast.wryday.com/turbo/maps/#garrett

i think i found a compressor map for a .42 T3 when doing a uni assignment, will have a look!

EDIT - is this any good to you...

http://not2fast.wryday.com/turbo/maps/#garrett

- xrsi

- XR(ustyAtTheMo)SI

- Posts: 7351

- Joined: Thu Jan 01, 1970 1:00 am

- Location: shropshire

heeman10 :Mark - Yup, but it's a pretty turd wastegate arrangement in terms of flow, even in relation to the T2!!

Flange, airflow, closed door, blocked?

- Excursion

- Bulletin Board User

- Posts: 15265

- Joined: Thu Jan 01, 1970 1:00 am

- Location: Skynet

- Your car: Ford Fiesta

Car: 1990 Ford Fiesta XR2i

James - No, the wastegate isn't visible from above etc, but it would still look nasty as a fixing! Those compressor maps don't state what A/R the housing was, only compressor trims, did you find any others on your journeys?

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Update

Turbo destroyed :lol:

To make the wastegate lever arm accessible for welding, the outer exhaust housing cover had to be removed, held on with five 1/2"-headed bolts. Naturally, one sheared off with little effort, and today I attempted to remove it. About 1mm was left poking out, so I first tried sawing a slot in it to use a screwdriver. That was fruitless, so I next tried chiselling it round...also without success.

Next I drilled a small hole through the centre, and let some release agent settle in for a while. I then tried a left-handed easy-out, which was a pretty cheap one I found in the workshop, and it sheared off in the bolt! So, I now have an exhaust housing with a bolt sheared off in it, and a 5mm length of tool steel sheared off inside that

Needless to say, Turbo Technics will be collecting the whole lot tomorrow The mess will be machined out of the exhaust housing, and a new actuator pin welded onto the wastegate arm so I can finally bolt it all back on and drive it. I much prefer doing these things myself to learn and save money, but sometimes you need the experts with their proper machinery to save the day.

The mess will be machined out of the exhaust housing, and a new actuator pin welded onto the wastegate arm so I can finally bolt it all back on and drive it. I much prefer doing these things myself to learn and save money, but sometimes you need the experts with their proper machinery to save the day.

*Defeated*

Turbo destroyed :lol:

To make the wastegate lever arm accessible for welding, the outer exhaust housing cover had to be removed, held on with five 1/2"-headed bolts. Naturally, one sheared off with little effort, and today I attempted to remove it. About 1mm was left poking out, so I first tried sawing a slot in it to use a screwdriver. That was fruitless, so I next tried chiselling it round...also without success.

Next I drilled a small hole through the centre, and let some release agent settle in for a while. I then tried a left-handed easy-out, which was a pretty cheap one I found in the workshop, and it sheared off in the bolt! So, I now have an exhaust housing with a bolt sheared off in it, and a 5mm length of tool steel sheared off inside that

Needless to say, Turbo Technics will be collecting the whole lot tomorrow

*Defeated*

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Ballache!

Least you have another car to drive round in!!

How come the bolts shear off so easily? Sure someone else had the same problem... can't you have some lube on them when they get fitted?

Least you have another car to drive round in!!

How come the bolts shear off so easily? Sure someone else had the same problem... can't you have some lube on them when they get fitted?

- mike_wall15

- Elite Post Master

- Posts: 6475

- Joined: Fri Jul 18, 2003 7:17 pm

- Location: Land of the Stars!

Car: 2002 BMW M3

Yeah, I've got the Mk6, and it's the end of show season, so I'm not bothered really  This happens a lot, and I'll be asking Turbo Technics if it can all be re-assembled with copper grease or something to help. They corrode and seize solidly in the turbine housings, so the slightest bit of grease would help. I'll await their suggestions

This happens a lot, and I'll be asking Turbo Technics if it can all be re-assembled with copper grease or something to help. They corrode and seize solidly in the turbine housings, so the slightest bit of grease would help. I'll await their suggestions

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Yeah, surely the right bit of grease with a high melting point would be fine! Alternatively, if they don't do it, if you know the torque settings then maybe you could do it when you get it back? The bolts won't have had time bond and break like this time!

- mike_wall15

- Elite Post Master

- Posts: 6475

- Joined: Fri Jul 18, 2003 7:17 pm

- Location: Land of the Stars!

Car: 2002 BMW M3

ahh balls  oh well will be sorted....

oh well will be sorted....

my T28 hybrid should be off the cossie next week so i'll be looking into fitting it to the fiesta along with my new head to give me more chance of breaking it on the way to meet you all at the next show

along with my new head to give me more chance of breaking it on the way to meet you all at the next show

my T28 hybrid should be off the cossie next week so i'll be looking into fitting it to the fiesta

- MAD_Adamski

- Elite Post Master

- Posts: 4475

- Joined: Thu Sep 19, 2002 6:28 pm

- Location: birmingham/shropshire Drives:Fiesta RS, Escort cosworth

- Excursion

- Bulletin Board User

- Posts: 15265

- Joined: Thu Jan 01, 1970 1:00 am

- Location: Skynet

- Your car: Ford Fiesta

Car: 1990 Ford Fiesta XR2i

All boxed up and good to go. My dad's not too happy as I snaffled one of his wood chisels to try and shock the bolt to turn in the hole, as no metal chisel would be small enough. Needless to say it broke into quite a lot of pieces after some persistent bashing, but nothing else was suitable for the job. He was also keen to try more techniques to release the easy-out and bolt, but rather than making a total write-off of the housing, I'll let the pro's do it as one more sheared bolt removal - they'll see hundreds every year no doubt. Tell you what - I can't wait to bolt it onto the engine again!

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

bad news that yo couldnt sdo it yourself, but at least it'll get sorted and be done by people who probably as you mentioend " deal with this kinda thing all the time"

enjoy the mk6's luxury

enjoy the mk6's luxury

- garyhurn77

- Post Master

- Posts: 906

- Joined: Tue Jul 26, 2005 9:57 am

- Location: magor, south wales

heeman10 :Mark - Yup, but it's a pretty turd wastegate arrangement in terms of flow, even in relation to the T2!! I want a compressor map for this turbo, but can't even find a .42 A/R T3 compressor map, let alone one for this particular impellor trim! It's running a touch rich now, so I'm thinking of taking it to MSD for a "setup", which is pretty damn in-depth, and I wouldn't mind nudging the boost up a bit if it would be worth it efficiency-wise.

.42 A/R T3 compressor map? I really dont think there is such thing

You can check flowcharts for compressors but not for their housings.

What turbo is this? P/N or from what car will help. Knowing this I'll let you know the turbo's std spec

- BUTRE

- Post Master

- Posts: 595

- Joined: Sun Jul 20, 2003 11:55 am

- Location: Behind the FRST wheel!

Garrett T3, exhaust housing is 0.36 A/R, compressor housing is 0.42 A/R ratio. I don't know the trims, only A/R ratios for the two housings. The turbo is down at Turbo Technics now so I can't measure the impellor wheel. The A/R ratio is the most useful information I have, given that I know it's of T3 origin. Another T3 with similar housing is likely to have a similar wheel - best I can do with I know so far! I'll be measuring the impellor diameters when it returns, as I would like to run a couple of pounds more boost.

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Is it from a ERST?

You need to measure this:

What gives you lag is the ex A/R housing. Compressor wheel doesn't affect almost at all the lag but its Trim says where is the surge line, efficiency and turbos durability due to its rpm.

0.36 ex housing on a 1.8 gives you really no lag. 2500rpm and you got full boost? Going 0.48 would give you 1000rpm more lag but alot less high rpm ex restriction (free bhp )

)

You should take it wisely since I've seen ppl upgrading their turbo, keeping the same boost and going really lean!!! Upgrade the turbo and only then go for another live map.

It's all about less restritive ex A/R housing (freeing bhp at top end) and more efficient compressor wheel (lower ACT's, etc at same boost).

It's not that difficult to know what turbo suits your engine best...

You need to measure this:

What gives you lag is the ex A/R housing. Compressor wheel doesn't affect almost at all the lag but its Trim says where is the surge line, efficiency and turbos durability due to its rpm.

0.36 ex housing on a 1.8 gives you really no lag. 2500rpm and you got full boost? Going 0.48 would give you 1000rpm more lag but alot less high rpm ex restriction (free bhp

You should take it wisely since I've seen ppl upgrading their turbo, keeping the same boost and going really lean!!! Upgrade the turbo and only then go for another live map.

It's all about less restritive ex A/R housing (freeing bhp at top end) and more efficient compressor wheel (lower ACT's, etc at same boost).

It's not that difficult to know what turbo suits your engine best...

- BUTRE

- Post Master

- Posts: 595

- Joined: Sun Jul 20, 2003 11:55 am

- Location: Behind the FRST wheel!

tough breaks James, those bolts do love to shear dont they? Sometimes its better to admit defeat thou.

:2004 Merc Vito: - :1983 Nissan Datsun 280zx: - :1992 GT Pro Series: - :2012 Mondraker Dune R:

- ~nomad~

- Elite Post Master

- Posts: 12504

- Joined: Fri Jan 18, 2002 12:00 am

- Location: hertfordshire

- Your car: Breadvan

BUTRE - Yep, all the reasons you've gone over again are reasons for me sticking with this turbo. I have no plans to change anything on this engine now.

Dave - Too right they love to shear! I wanted to try all I could before admitting defeat - they made light work of it

Update

Firstly, some pics I took before sending it to Turbo Technics.

A small crack in the exhaust housing - nothing major or unique (top centre of the port, just before it curves away):

The fiendish bolt. I managed to drill into it ok, but the easy-out tool snapped...again, before I'd even got half-decent torque into it. That also became nicely wedged in my exhaust housing:

Turbo all ready to be sent off to Turbo Technics to have the bolt removed, and a new actuator pin welded onto the wastegate arm:

I sent it away the Friday before last, and it came back yesterday Exhaust housing end cap all blasted off and looking tidy, with all the crummy bolts replaced with studs and fresh nuts:

Exhaust housing end cap all blasted off and looking tidy, with all the crummy bolts replaced with studs and fresh nuts:

They also fitted a new wastegate lever arm, along with the new actuator pin welded in (this is the weld that originally failed, causing me to lose boost):

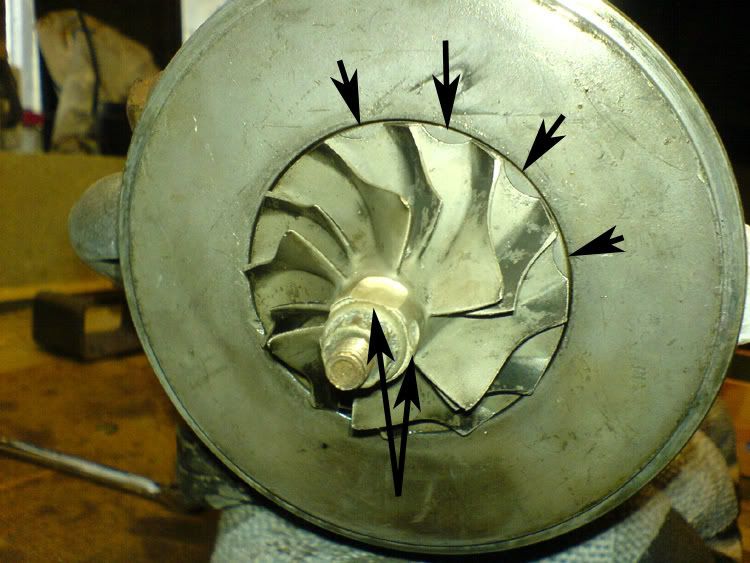

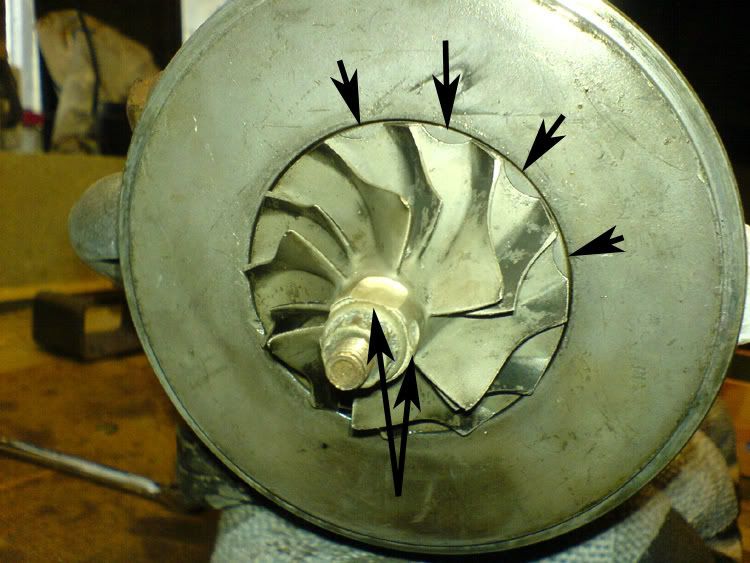

A shot of my impellor. I noticed, when I removed it from the car and inspected it, that there was a small amount of foreign object damage on the very tips of the major compressor blades. Turbo Technics also commented on this when they got to work on the turbo. Since I'd already felt that the bearings were absolutely rock solid still, and the turbo was making no unusual noises and was still making correct boost, I opted to leave the wheel in place. Note the various pieces of material removed for the original balancing also:

Back on the exhaust manifold and ready to rock

Fitted it all back in yesterday afternoon, note the blanked off dump valve hoses

Nice and fresh and ready to make noises again! I had to remove the turbo insulation, and will leave it off for now to allow me to monitor the actuator pin and possibly adjust the actuator preload if necessary:

Just need to top the coolant up, get the charge carrier back on and have a play. I've missed it

Dave - Too right they love to shear! I wanted to try all I could before admitting defeat - they made light work of it

Update

Firstly, some pics I took before sending it to Turbo Technics.

A small crack in the exhaust housing - nothing major or unique (top centre of the port, just before it curves away):

The fiendish bolt. I managed to drill into it ok, but the easy-out tool snapped...again, before I'd even got half-decent torque into it. That also became nicely wedged in my exhaust housing:

Turbo all ready to be sent off to Turbo Technics to have the bolt removed, and a new actuator pin welded onto the wastegate arm:

I sent it away the Friday before last, and it came back yesterday

They also fitted a new wastegate lever arm, along with the new actuator pin welded in (this is the weld that originally failed, causing me to lose boost):

A shot of my impellor. I noticed, when I removed it from the car and inspected it, that there was a small amount of foreign object damage on the very tips of the major compressor blades. Turbo Technics also commented on this when they got to work on the turbo. Since I'd already felt that the bearings were absolutely rock solid still, and the turbo was making no unusual noises and was still making correct boost, I opted to leave the wheel in place. Note the various pieces of material removed for the original balancing also:

Back on the exhaust manifold and ready to rock

Fitted it all back in yesterday afternoon, note the blanked off dump valve hoses

Nice and fresh and ready to make noises again! I had to remove the turbo insulation, and will leave it off for now to allow me to monitor the actuator pin and possibly adjust the actuator preload if necessary:

Just need to top the coolant up, get the charge carrier back on and have a play. I've missed it

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Nice little update, and good pics, helps me to learn stuff!

Hope it didn't turn out too expensive in the end. You weren't tempted to undo the new nuts and bolts and lube them up?

Hope it didn't turn out too expensive in the end. You weren't tempted to undo the new nuts and bolts and lube them up?

- mike_wall15

- Elite Post Master

- Posts: 6475

- Joined: Fri Jul 18, 2003 7:17 pm

- Location: Land of the Stars!

Car: 2002 BMW M3

No it wasn't too expensive, and no, I can't say I was tempted to remove nuts and bolts. The nuts on the exhaust housing end cap shouldn't be an issue now, since it uses studs screwed into the exhaust housing with external nuts to secure the end cap to it. They've fitted all-new bolts to the exhaust housing side of the centre housing, so I'll leave them as they are. I think I may have had problem because the bolts in the turbo before were old and possibly not of a recommended type...Turbo Technics should know what works best anyway

An interesting point was that they too found that the actuator bracket flexes (you may/may not remember that I went to Fusion Fabrication and Lee made my actuator bracket up to help radiator clearance). We thought it may be a bit flexy, and that proved to be true when MSD were mapping it. TT did an actuator/wastegate check, and found the same thing, and at the end of the conversation he said "So we set the actuator back to 1.2 bar anyway". I only just about get 1 bar on high boost, then it eases off, which means I must be losing around 0.2 bar between the turbo and the inlet manifold - just under 3 psi. Quite a bit really! Next time the intercooler's off I might take it over to Lee to get bosses welded on for boost and temperature senders so I can see what's doing what.

An interesting point was that they too found that the actuator bracket flexes (you may/may not remember that I went to Fusion Fabrication and Lee made my actuator bracket up to help radiator clearance). We thought it may be a bit flexy, and that proved to be true when MSD were mapping it. TT did an actuator/wastegate check, and found the same thing, and at the end of the conversation he said "So we set the actuator back to 1.2 bar anyway". I only just about get 1 bar on high boost, then it eases off, which means I must be losing around 0.2 bar between the turbo and the inlet manifold - just under 3 psi. Quite a bit really! Next time the intercooler's off I might take it over to Lee to get bosses welded on for boost and temperature senders so I can see what's doing what.

- heeman10

- Elite Post Master

- Posts: 28746

- Joined: Fri Nov 08, 2002 5:32 pm

- Location: Somerset

- Your car: Audi TT TDI Quattro S line

Twitter

The second 20th Anniversary article, a dive into the history of how the site came about is available here: https://t.co/kbCfZ4sf0R

17:44, 4th December 2021 Twitter Web App

To celebrate https://t.co/wXVkvJipaS being 20 years old this year, I've written a series of articles detailing the… https://t.co/B0vE0Y3KvP

17:42, 4th December 2021 Twitter Web App

Follow fiestaturbo.com on Twitter:

http://twitter.com/fiestaturbo/

Facebook

New article! fiestaturbo.com is 20 years old this year and I'm writing a series delving into the history of it. …

Saturday, 4th December 2021 12:49

Some awesome Escorts from the Fair - FORD FAIR 2021: ESCORT EXHIBITION - …

Sunday, 31st October 2021 17:05

All the best Focuses from Ford Fair - FORD FAIR 2021: FOCUS PEEKING - Which was your …

Thursday, 7th October 2021 22:21

Become a fan:

http://www.facebook.com/fiestaturbo/

RSS Feeds

Subscribe to the RSS feed

What is RSS?

RSS is a technology that lets you use special applications or modern browsers to notify you you when a site is updated. You can then read the updated content in that application or your browser.

To subscribe to these RSS feeds you need to copy the links above. For instructions on how to add it to the feeds you keep track of, consult the documentation of your RSS reader.